What Kind Of Sensor Normally Used In The Arcade Basketball Games Machine?

Reflective photoelectric sensor is a sensor in which the transmitter and receiver are installed in the same device, and a reflector is installed in front of it. It can be used to detect the changes in the brightness and color of the ground, and it can also detect whether there is an approaching object.

Advantages of the sensor

- Easy to install and wire

- Easy to align the light path during installation and use

- Not affected by the shape, color and material of the object to be inspected

- Compared with the through-beam photoelectric sensor, it saves space

- Application range:amusement park、Family entertainment center、game center、shopping mall

Precautions

- The surface of object to be inspected must have black and white parts for absorbing and reflecting infrared light, so that the receiving tube can be effectively cut off and saturated to achieve the purpose of counting.

- The most critical point is that the receiving tube must work in the cut-off zone and the saturation zone.

- The front board of the reflective photoelectric sensor must be parallel to the surface of the detected object. Then the conversion efficiency of the reflective photoelectric sensor can be the highest.

- Keep the distance between the front board of the reflective photoelectric sensor and the reflector within specified range.

- The reflective photoelectric sensor must be installed where there is no direct exposure to strong light. Because the infrared light in the strong light will affect the normal operation of the receiving tube.

- When the current of the infrared emitting tube of the reflective photoelectric sensor is between 2 and 10ma, the linearity of the luminous intensity and current is the best. The current value generally does not exceed this range.

- If the value is too high, the light attenuation of the emitting tube will also working for a long time. The current value of the battery power supply should be low, then the anti-interference performance can be reduced.

- It should be considered in the structural design, and try to avoid adverse factors such as external light interference.

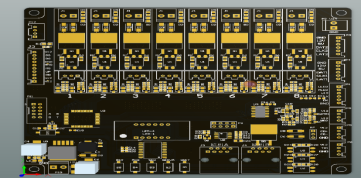

- When installing and soldering, the minimum distance between the root of the reflective photoelectric sensor and the pad should not be less than 5mm, otherwise the die will be easily damaged during soldering.

- Or cause changes in die performance. The welding time should be less than 4 seconds.

- The best working condition parameter setting of the reflective photoelectric sensor is in the specific working environment: select the model of the reflective photoelectric sensor according to the actual detection distance.